Product

Automatic Syrup Filling Oral Liquid Filling Capping Machine

Details:

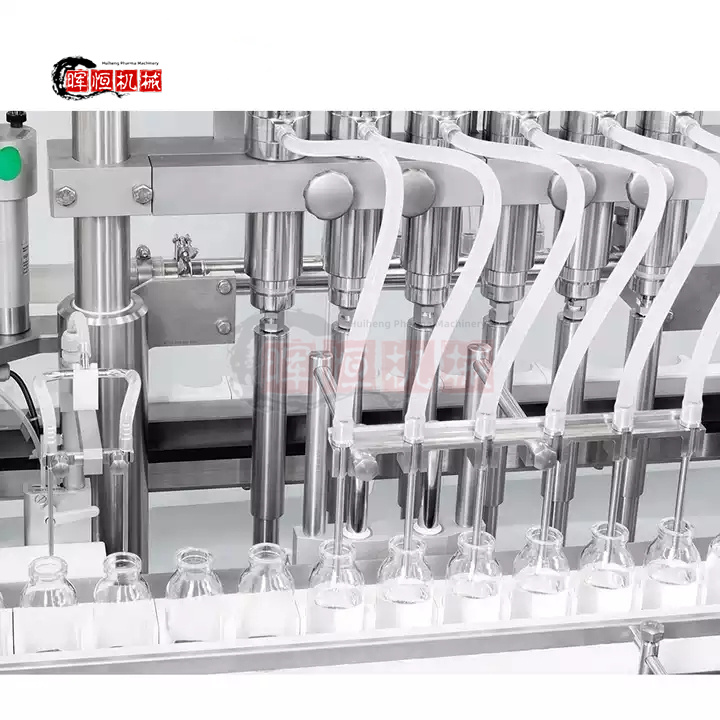

- Adopts plunger type metering pump filling, high precision;The structure of pump adopts fast disassembly institutions, easy to clean and disinfect.

- PLC control system, color touch screen display, machine has function of counting automatically.

- The filling nozzle was equipped with drip-proof device.

- When filling liquid, the filling nozzle dive into the bottom of bottle, rising slowly, it can effectively prevent bubbles

Description

Application

Usage:

The Automatic Liquid Filling and Capping Machine can automatically finish the bottle filling, bottle capping. With the no bottle no filling feature. The machine with scientific structure can be single used, and also can be used with production line .It is the ideal liquid filling production equipment, completely meet with GMP requirements.

This machine is mainly used for syrup, drinks, soybean sauce, vinegar, cod-liver oil, olive oil, liquid calcium, wine, liquid fertilizer, essential oil, toner, hair oil, laundry detergent, ink, disinfectant, injection, industrial alcohol and various medical liquid filling and capping.

Used for small vial liquid filling and capping in pharmaceutical, chemical, and food industry. Based on domestic and international advanced technology, we developed our new oral liquid production line. It can automatically complete bottle in-feed, arrange bottle, adjusting filling quantity, unscramble cap, capping, out-feed procedure.

Feature

1. Adopts plunger type metering pump filling, high precision;The structure of pump adopts fast disassembly institutions, easy to clean and disinfect.

2. PLC control system, color touch screen display, machine has function of counting automatically.

3. The filling nozzle was equipped with drip-proof device.

4. When filling liquid, the filling nozzle dive into the bottom of bottle, rising slowly, it can effectively prevent bubbles.

5. Machine body is made of 304 stainless steel, full compliance with GMP standard.

Technical Parameters

| Model | SHH-OYT4 | SHH-OYT8 |

| Filling head number | 4 | 8 |

| Capping head number | 1 | 2 |

| Filling volume | 10-50ml/50-500ml | 10-50ml/50-500ml |

| Capacity | 10-40 bottles/min | 40-80 bottles/min |

| Filling accuracy | ≥99% | ≥99% |

| Pass rate | ≥ 98% | ≥ 98% |

| Power supply | 1Ph.220V, 50/60Hz | 1Ph.220V, 50/60Hz |

| Pass rate | ≥ 99% (Depends on quality of packing material) | ≥ 99% (Depends on quality of packing material) |

| Power | 0.6-0.8Mpa | 0.6-0.8Mpa |

| Power | 1.6kw | 2.2kw |

| Net weight | 600kg | 800kg |

| Machine dimension | L2200*W1500*H1900mm | L2600*W1600*H2000mm |

Tablet Example

Video

Related Products

Contact Us

Phone

008613166139318

kevinpharmachinery@gmail.com

kevin-pharmachinery

Get in Touch with Us

Contact Us

Our professional team will reply to you as soon as possible.

kevinpharmachinery@gmail.com

WhatsApp/Phone/Wechat

008613166139318

Company name

Shanghai Huiheng Pharmaceutical Machinery Co., Ltd.