Product

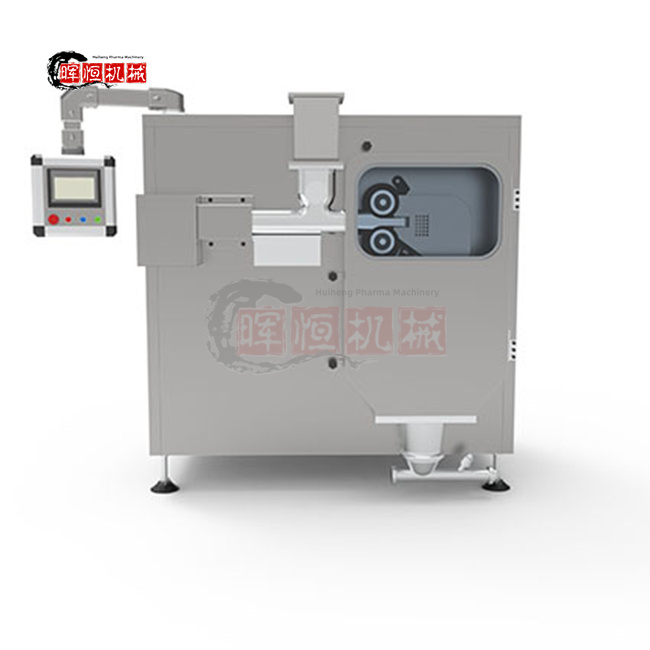

SHH-LG Series Roller Compactor Dry Granulator for cephalexin

Details:

- Material is formed by mechanical compactor, its chemical properties will not be destroyed, and effective content will not be reduced.

- Low energy consumption and high productivity. The granulation rate can be 85% for 8~60 mesh granules.

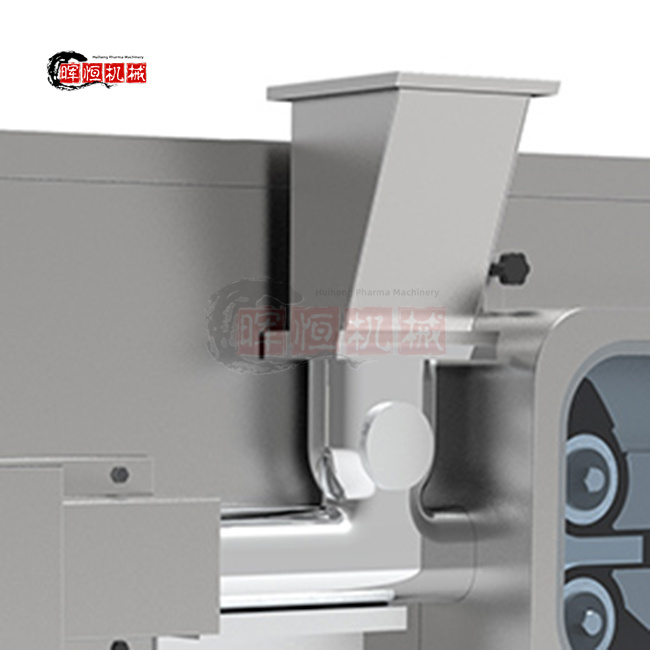

- Structure is simple and fastening part is less. It is convenient to install and disassembly the equipment. The disassembling time is less than 8min, and installation time is less than 8min.

- Sealing efficiency is good and there is no leakage. So it can ensure the safety of operator and drugs.

Description

Application

General description of Roller Compactor/Dry Granulator

Roller Compactor is also called Dry Granulator. It is a new high efficient type granulating equipment that can make powder to granules directly, and the working process does not need adding water, stirring or drying. It is widely used in pharmaceutical, chemical and food industry. It has a lot of advantages, so it in widely used in all kinds of industries for treating active materials, especially suitable for heat-sensitive drugs.

Feature

- Material is formed by mechanical compactor, its chemical properties will not be destroyed, and effective content will not be reduced.

- Low energy consumption and high productivity. The granulation rate can be 85% for 8~60 mesh granules.

- Structure is simple and fastening part is less. It is convenient to install and disassembly the equipment. The disassembling time is less than 8min, and installation time is less than 8min.

- Sealing efficiency is good and there is no leakage. So it can ensure the safety of operator and drugs.

- When the machine is shut down, the automatic water-return function can avoid the leakage of cooling water when disassembling the equipment.

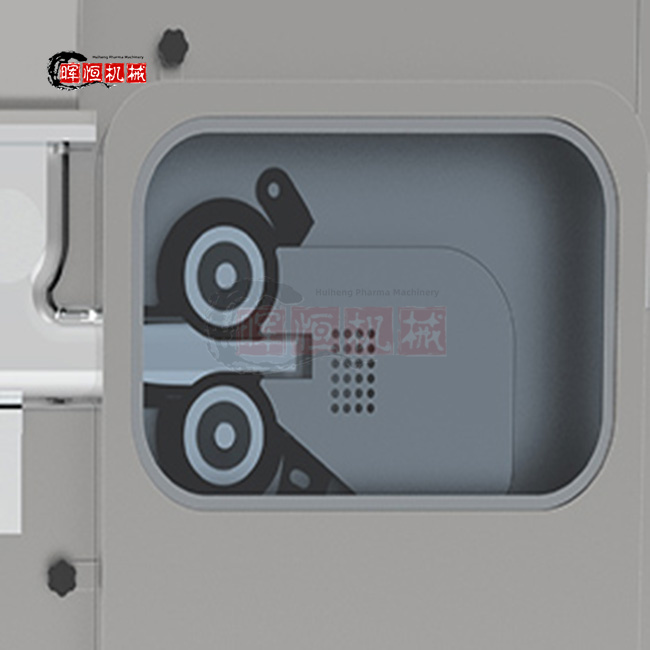

- The surface of roller can be checker type, straight type and plain type. They can meet the requirements of treating materials with different properties.

- The control system and main machine is in one body, and it is convenient for installation and commissioning.

- The gap of rollers is adjustable. So the density of lamina is even.

- There is hydraulic system, so the hardness and density of granules are adjustable.

- Two rollers and installed up and bottom type, this structure can eliminate the effect of gravity to material. So the uniformity of material before compacting can be ensured.

Technical Parameters

| Model | Capacity

(kg/h) |

Total power (kw) | Press wheel size

(Diameter×Width) |

| SHH-LG100 | 1.5~25 | 3.35 | 100×25 |

| SHH-LG100E | 12~40 | 4.43 | 100×40 |

| SHH-LG160 | 30~100 | 6.3 | 160×50 |

| SHH-LG200 | 80~200 | 11.24 | 200×75 |

| SHH-LG200E | 120~250 | 14.24 | 200×100 |

| SHH-LG240 | 200~420 | 15.94 | 240×100 |

| SHH-LG360 | 350~750 | 28.24 | 360×150 |

| SHH-LG500 | 600~1200 | 35 | 500×200 |

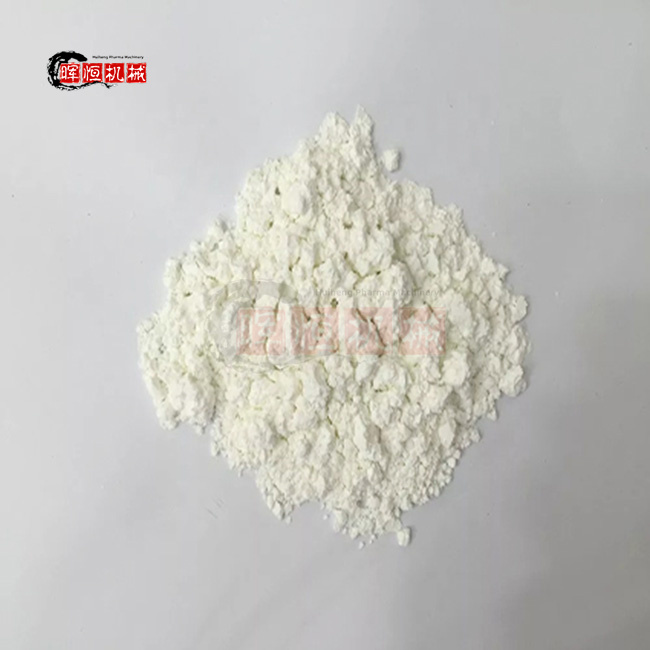

Tablet Example

Video

Related Products

Contact Us

Phone

008613166139318

kevinpharmachinery@gmail.com

kevin-pharmachinery

Get in Touch with Us

Contact Us

Our professional team will reply to you as soon as possible.

kevinpharmachinery@gmail.com

WhatsApp/Phone/Wechat

008613166139318

Company name

Shanghai Huiheng Pharmaceutical Machinery Co., Ltd.