Product

SHH-GHL Series High Speed Wet Type Mixing Granulator

Details:

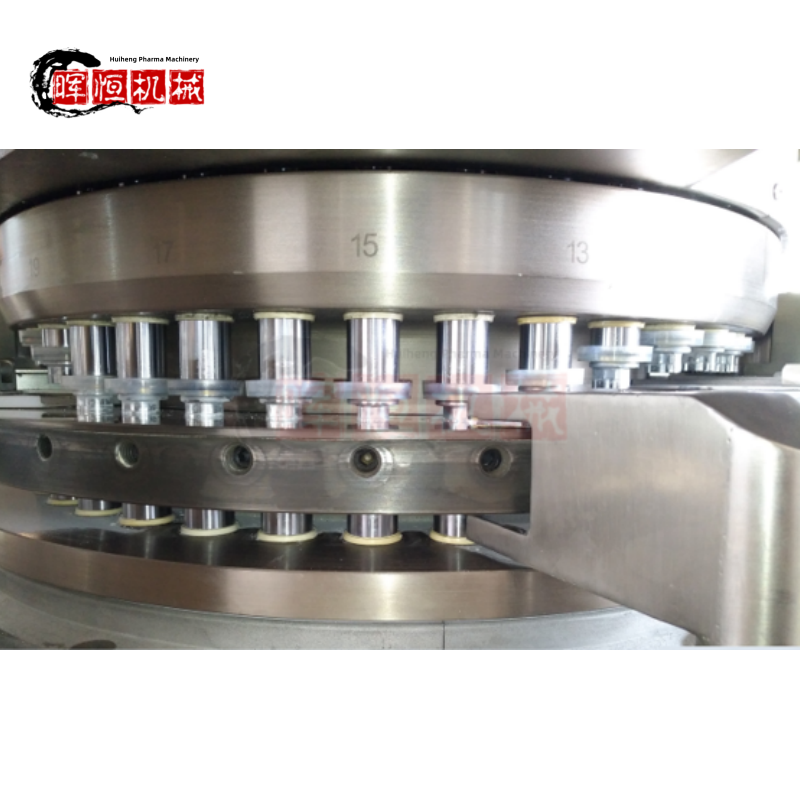

- The High speed SHH-GHL series wet type mixing granulator adopts a practical horizontal cylinder structure.

- The driving shaft is euipped with inflatable seal. While washing, the air can be replaces by water.

- Fluidized granulating processed is used and the final granules are quite round with high fluidity.

- Compared with traditional technique, this type of machine can reduce 25% of adhesive and also shorten the drying time.

Description

Application

The High Speed SHH-GHL series wet type high speed mixing granulator is an advanced wet granulator which can effectively mix the target materials to turn out finequality wet granules, and is widely applied by the trades of foodstuff, chemical, powder metallurgy, and dyeing etc.

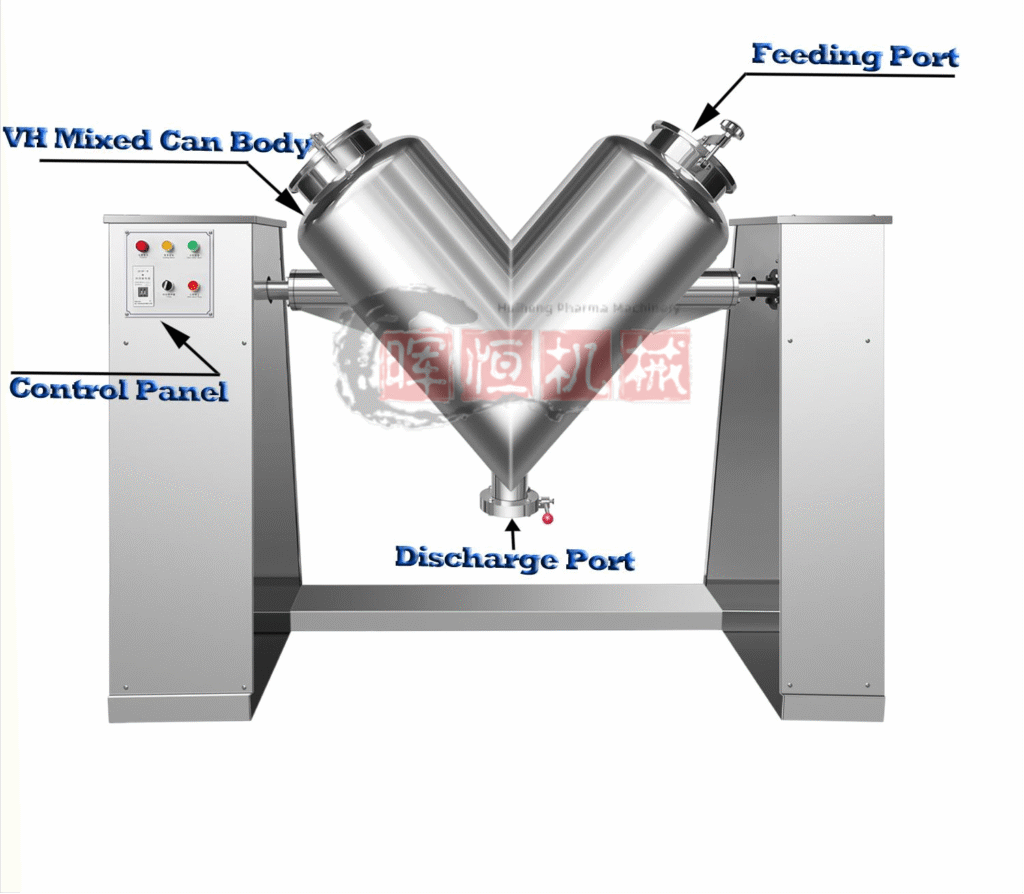

Feeding the main materials and auxiliary materials that need to be granulated into the mixer tank in appropriate proportions and formulas. The powder materials and binders are fully mixed at high speed by the bottom mixing paddle in the cylindrical container to form moist soft materials. The side-mounted high-speed crushing paddle cuts into uniform wet particles, thereby achieving the purpose of granulation. Vacuum drying and auxiliary system equipment can also be selected to achieve one step and directly obtain the finished product.

Food and feed, Ceramic products, Plastic, rubber, tires, Polymers and resins, Biochemical products, Chemicals and Fertilizers, Perfume, Pigments and dyes, Vegetable and plant extracts, Fragrance, Food crops.

Feature

- The High speed SHH-GHLseries wet type mixing granulator adopts a practical horizontal cylinder structure.

- The driving shaft is euipped with inflatable seal. While washing, the air can be replaces by water.

- Fluidized granulating processed is used and the final granules are quite round with high fluidity.

- Compared with traditional technique, this type of machine can reduce 25% of adhesive and also shorten the drying time.

- For each batch of material, with 2 minutes dry mixing and 1-4 minutes granulating, the efficiency is 4-5 times higher than that of traditional technique.

- Dry mixing, wet mixing and granulating are finished inside the same sealed container, which is in conformity with the requirement of GMP.

Technical Parameters

| Model | SHH-GHL50 | SHH-GHL150 | SHH-GHL200 | SHH-GHL250 | SHH-GHL300 | SHH-GHL400 |

| Volume (L) | 50 | 150 | 200 | 250 | 300 | 400 |

| Capacity(kg/batch) | 15 | 50 | 80 | 100 | 130 | 200 |

| Mixing speed(rpm) | 200/400 | 180/270 | 180/270 | 180/270 | 140/220 | 106/155 |

| Mixing power(kw) | 4/5.5 | 6.5/8 | 9/11 | 9/11 | 13/16 | 18.5/22 |

| Cutting speed(rpm) | 1500/3000 | 1500/300 | 1500/300 | 1500/300 | 1500/300 | 1500/300 |

| Cutting power(kw) | 1.3/1.8 | 2.4/3 | 4.5/5.5 | 4.5/5.5 | 4.5/5.5 | 6.5/8 |

| Amount of compressed air(m³/m) | 0.6 | 0.9 | 0.9 | 0.9 | 1.1 | 1.5 |

Tablet Example

Video

Related Products

Contact Us

Phone

008613166139318

kevinpharmachinery@gmail.com

kevin-pharmachinery

Get in Touch with Us

Contact Us

Our professional team will reply to you as soon as possible.

kevinpharmachinery@gmail.com

WhatsApp/Phone/Wechat

008613166139318

Company name

Shanghai Huiheng Pharmaceutical Machinery Co., Ltd.

_副本.png)