Product

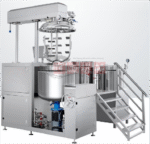

SHH-SME Double Cylinder Hydraulic Lift Vacuum Homogeneous Emulsifier Mixer

Details:

- For material of super high viscosity(above 50,000C.P.S), the high viscosity vacuum emulsifying homogenizer is highly recommonded.

- Raw materials can be directly sucked into the groove by the machine.

- The machine is provided with vacuum, hydraulic pressure, heating, cooling and other functions

Description

Application

It is suitable for production of ointment and cream products in cosmetic and pharmaceutical plants.The emulsifying effect is more prominent for materials of high base viscosity and high solid content.

Vacuum emulsifier is professionally designed according to the ointment manufacturing process of cosmetics and ointments etc. products through introducing advanced technology from abroad. The machine unit is composed of pre-treating boiler, vacuum emulsifying and blending boiler, vacuum pump, hydraulic system, dumping system, electric control system and work platform etc. The machine unit is featured by simple operation, stable performance, good homogenizing performance, high production efficiency,convenient cleaning, reasonable structure, small and area and high automatic degree etc. High speed rotor endows the material with high centrifugal speed and great centrifugal force.

When slowing down instantaneously, the material suffers the associative action of cavitation, detonation, shearing and grinding. Meanwhile, the material is imbibed from upside of the homogenizer and erupted from the sideward plug hole. By the combined action of the stirrer along the vessel wall, granule spreads homogeneously and uniformly and the degree of uniformity shall come up to more than 99%. Very small aperture between stator and rotor shall assure the effect of grinding, shearing,mixing and emulsifying of the material and avoid colliding and friction when the rotor rotates with high speed.

Feature

●For material of super high viscosity(above 50,000C.P.S), the high viscosity vacuum emulsifying homogenizer is highly recommonded.

●Raw materials can be directly sucked into the groove by the machine.

●The machine is provided with vacuum, hydraulic pressure, heating, cooling and other functions.

●Emulsifying, blending and dispersion can be completed within a short period of time.

●Slow speed blade type blending and high speed homogenizing systems are provided with frequency conversion control.

●Users can select pushbutton control or PLC touch screen system.

●Parts that contact materials are made of stainless steel SUS316L. The whole equipment conforms to GMP standard.

●Blending is carried out under vacuum to effectively ensure the emulsifying effect.

●The equipment is provided with the CIP cleaning device, which can conveniently use the self-contained CIP cleaning system of users to clean the equipment.

Technical Parameters

| Model | Workng Volume | Heating Method optonal | Overall Dimension

(L*W*H)M |

Weight(Kg) |

| SHH-SME50 | 50 | Electric heating or steam heating | 2.6×2.4×2 | 650 |

| SHH-SME100 | 100 | 2.8×2.5×2.2 | 850 | |

| SHH-SME200 | 200 | 3×2.8×2.3 | 1100 | |

| SHH-SME500 | 500 | 3.3×3×2.5 | 1500 | |

| SHH-SME1000 | 1000 | 4.2×3.5×3.8 | 2500 |

Tablet Example

Video

Related Products

Contact Us

Phone

008613166139318

kevinpharmachinery@gmail.com

kevin-pharmachinery

Get in Touch with Us

Contact Us

Our professional team will reply to you as soon as possible.

kevinpharmachinery@gmail.com

WhatsApp/Phone/Wechat

008613166139318

Company name

Shanghai Huiheng Pharmaceutical Machinery Co., Ltd.