Product

Automatic Vial Bottle Filling Stoppering Capping Production Line for Powder

Details:

- Applicable specification: 5ml-50ml vial (as per user’s requirement)

- Production Capacity: 6000-30000BPH for Machinery Vial Powder Screw Filling Capping Production Machine

- Number of filling head: 1-4, to be selected according to output

- Filling Accuracy: ≤ ±2%.

- Capping qualified rate: ≥99.9% for Machinery Vial Powder Screw Filling Capping Production Machine

Description

Application

Main description:

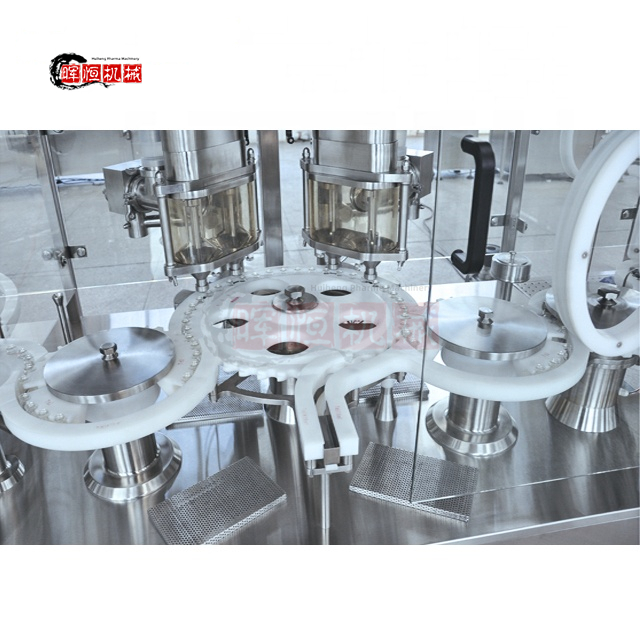

Vial powder filling and stoppering machine, the core design of the powder filling machine is to use the combination of servo motor and updated auger, which ensures the accuracy of the filling dosage. With the exact amount of powder filled in, rubber stopper will then be automatically sealed on top of each vial.

Automatic vial powder filling and capping machine is suitable for distributing powder products for medium and large factory,such as antibiotics, biochemical with automatic stoppering function. This machine is suitable for antibiotic glass bottle, rubber bottle stopper, and out cap capper, machine can be customed according to different bottle size and cap size.

Feature

Main features:

- Low speed rotary powder filling machine SHH-FGB2-dual intermittent feeding, filling and stoppering

- High speed rotary powder filling machine SHH-FGP4 Continuous feeding, stoppering; intermittent filling. Automate rejecting and sampling. No vial no filling; no vial no stoppering.

- Linear powder filling machine SHH-FGZ2- Dual continuous feeding, stoppering; intermittent filling. Automate rejecting and sampling. No vial no filling; no vial no stoppering.

- Powder filling screw capping machine SHH-FGX2- Dual intermittent feeding, filling and screw capping

Technical Parameters

| Description | Low speed rotary powder

filling machine |

High speed rotary powder

filling machine |

Linear powder filling

machine |

Powder filling screw

capping machine |

| Model | SHH-FGB2 | SHH-FGP4 | SHH-FGZ2 | SHH-FGX2 |

| 7ML | 7200 | 22000 | 15000 | 6000 |

| 10ML | 7200 | 22000 | 15000 | 6000 |

| 15ML | 6000 | 19000 | 12000 | 5400 |

| 20ML | 5600 | 16800 | 12000 | 5400 |

| 25ML | 4900 | 15000 | 10000 | 4800 |

| 30ML | 4800 | 12000 | 10000 | 4800 |

| Power supply | 380V/50Hz/3Phases | |||

| Vacuum | -0.066MPa, 8m³/h | -0.066MPa, 14m³/h | -0.066Pa, 10m³/h |

-0.066Pa, 8m³/h |

| Power | 1KW | 6KW | 3KW | 3KW |

| Noise Level | ≤65db | ≤65db | ≤65db | ≤65db |

| Max Capacity | 7200 | 22000 | 15000 | 6000 |

| Tolerance | ≤±2% | ≤±2% | ≤±2% | ≤±2% |

| Completion rate | 99.5% | 99.5% | 99.5% | 99.5% |

| Dimension | 1800*940*1800 | 3240*1100*1800 | 2330*1320*1800 | 1955*1188*1800 |

| Feeding height | 900±20mm | 900±20mm | 900±20mm | 900±20mm |

| Weight | 860KG | 1400KG | 1100KG | 1000KG |

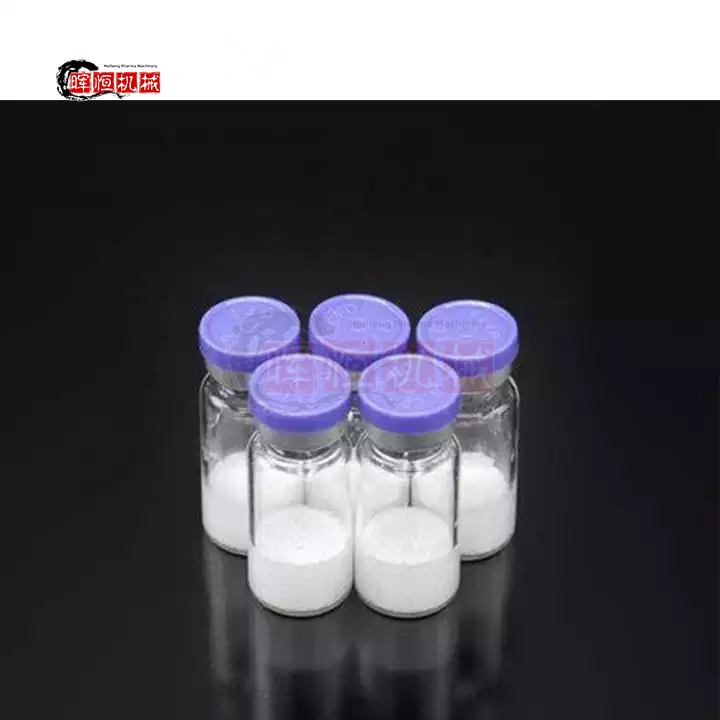

Tablet Example

Video

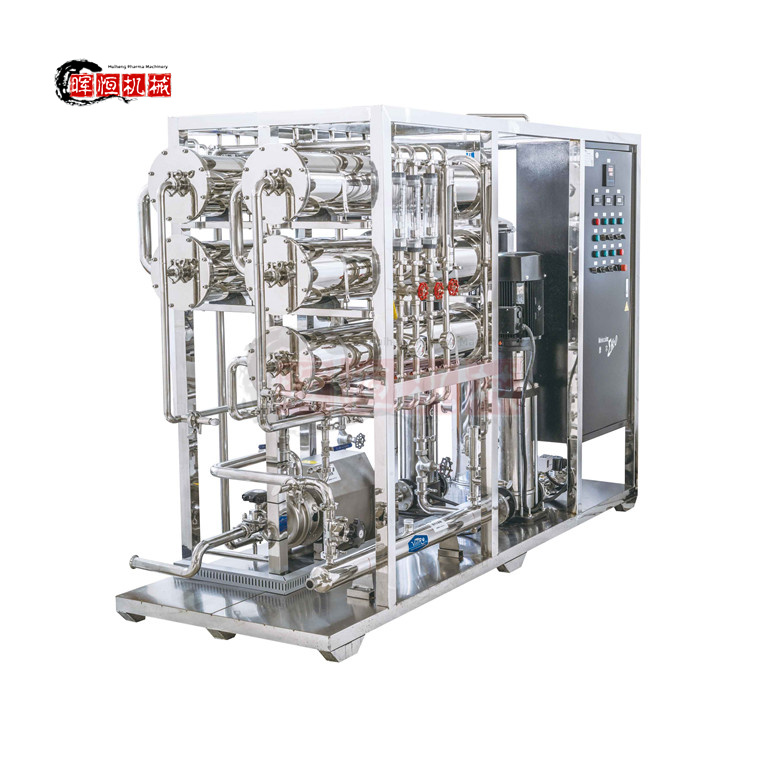

Related Products

Contact Us

Phone

008613166139318

kevinpharmachinery@gmail.com

kevin-pharmachinery

Get in Touch with Us

Contact Us

Our professional team will reply to you as soon as possible.

kevinpharmachinery@gmail.com

WhatsApp/Phone/Wechat

008613166139318

Company name

Shanghai Huiheng Pharmaceutical Machinery Co., Ltd.