Product

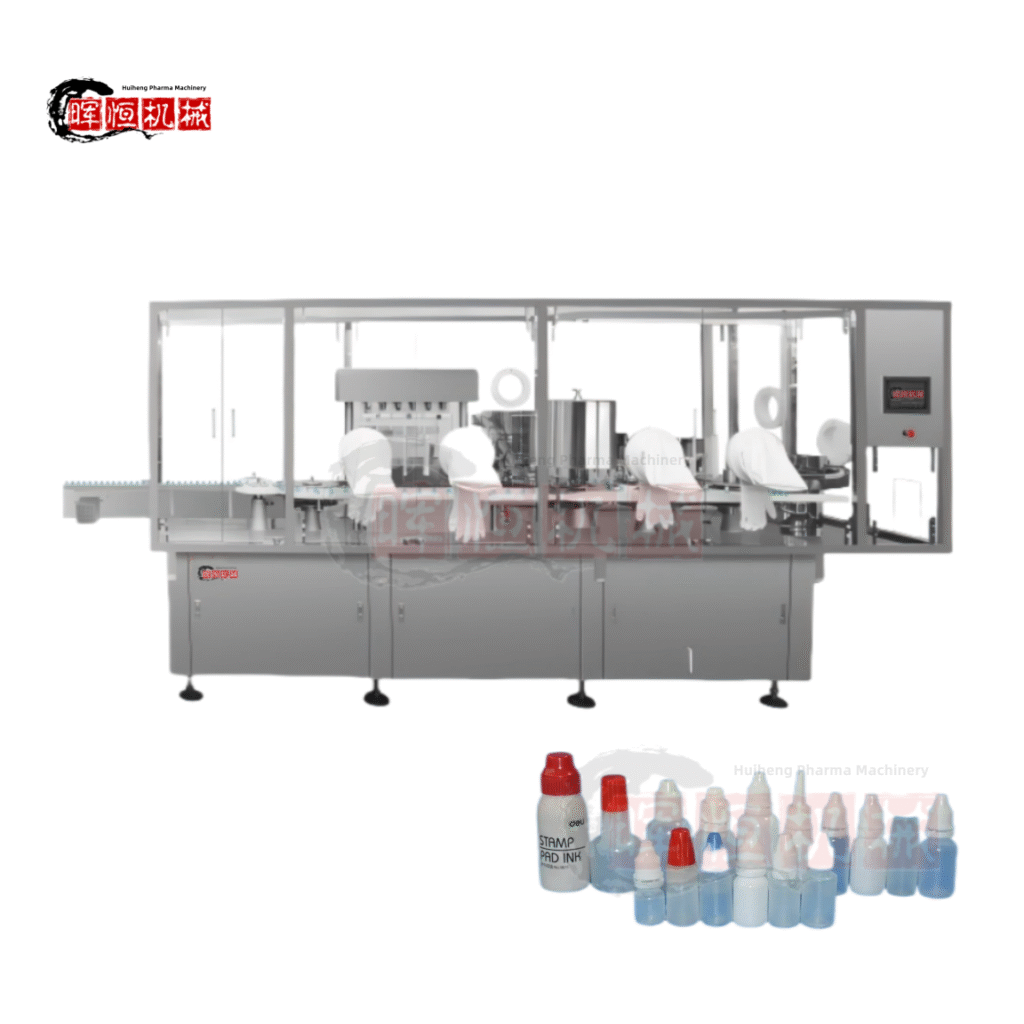

500ml Glucose Solution PP Bottle Washing Filling Sealing Production Line

Details:

- Servo driver and stable during high-speed movement, the positioning is accurate, durable, and the maintenance cost is low.

- The cam clamping fingers without plastic scrap and powder to ensure product quality.

- High production capacity: range from 4000-15000bottles per hour.

- Closed integral chain structure, precise center distance, rings and other foreign objects cannot enter the chain, easy maintenance.

- The sealing no air leak, improve the blowing efficiency, shorten the bottle forming time.

- With precise filling; accurate air discharging, can control the degree of deformation of the bottle after sterilization.

Description

Application

Description:

The machine is mainly used for the washing, filling and sealing of PP bottle infusion. It is suitable for hot sealing of combined cap, it includes ion wind washing unit, WFI washing unit, time-pressure filling unit, sealing unit/ capping unit.

The HUIHENG PHARMA Automatic PP Bottle IV Solution Production Line seamlessly integrates three essential components: the Preform/Hanger Injection machine, Bottle Blowing machine, and the Washing-Filling-Sealing machine. Engineered for automatic and intelligent operation, it ensures stable performance and easy maintenance. With heightened production efficiency and reduced operational costs, this production line delivers high-quality IV solution plastic bottles, establishing itself as the optimal choice.

The HUIHENG PHARMA Plastic Bottle Blowing machine is specifically designed for molding IV bottles and other PP bottles. Its multifunctional stations include preform loading, preform heating, preform delivery, blowing, and bottle extraction.

The HUIHENG PHARMA XGF PP Bottle LVP Wash-Fill-Seal Machine features three stations encompassing ionic air washing or a combination of ionic air with WFI washing, constant pressure filling, and hot melting sealing. Primarily designed for washing, filling, and sealing the production of PP plastic soft and hard bottles for large-volume parenterals such as glucose, sodium chloride, sodium chloride and glucose, metronidazole, etc. This sophisticated machine ensures precise and hygienic production processes.

Feature

- Compact structure and minimum operators. Except the operators monitoring bottle feeding, only one operator is required.

- Online iron generation monitor is provided. If static electricity quantity of washed bottle exceeds the set-point, there is no filling and capping and alarm will generate.

- Machine shuts down when one door is opened.

- Functions are provided, such as automatic cap unscrambling, cap feeding and no bottle no capping.

- The heating plate of the sealing device is provided with an anti-collision device.

- GMP compliant CIP&SIP function are provided.

- Bottle feeding chain connected to bottle blowing machine can be selected.

- Adjustable exhaust device for control deformation of bottles after sterilization

Technical Parameters

| Project | Unit | QTY | |||

| SHH(Q)30/24/24 | SHH30/30/24/24 | SHH(Q)48/40/56 | SHH42/48/40/56 | ||

| Capacity | bottles/min | 50-120 | 50-120 | 150-300 | 150-300 |

| Bottle shape and specifications | ml | 100/250/500 | |||

| Washing station | pcs | 30 | 30 | 48 | 42 |

| Water washing station | pcs | 30 | 48 | ||

| Filling station | pcs | 24 | 24 | 40 | 40 |

| Capping station | pcs | 24 | 24 | 56 | 56 |

| Main motor | KW | 3.7 | 3.7 | 5.5 | 5.5 |

| Cap collecting oscillator | KW | 0.5 | 0.5 | 0.5X2 | 0.5X2 |

| Ionic Wind | KW | 0.01X30 | 0.01X30 | 0.01X48 | 0.01X42 |

| Belt power | KW | 0.75 | |||

| Heat board | KW | 25 | 25 | 20X3 | 20X3 |

| Pure Air consumption

(0.5-0.7MPa) |

M3/min | 3-6 | |||

| WFI consumption | M3/min | 0.3-0.8 | 0.9-1.8 | ||

Tablet Example

Video

Related Products

Contact Us

Phone

008613166139318

kevinpharmachinery@gmail.com

kevin-pharmachinery

Get in Touch with Us

Contact Us

Our professional team will reply to you as soon as possible.

kevinpharmachinery@gmail.com

WhatsApp/Phone/Wechat

008613166139318

Company name

Shanghai Huiheng Pharmaceutical Machinery Co., Ltd.