Product

Automatic Tablet Capsule Counting Bottling Filling Production Line

Details:

- Auxiliary function :Photoelectric sensor can check automatically if there’s no bottle and stops automatically.

- Easy operation :Adopting intellectualized design, all kinds of operation data can beset according to the requirement.

- It can store 10 groups of setting parameters for use.

- Convenient maintenance :After simple training, the worker can operate easily.It is easyto disassembly, clean and change the components without any tools.

- Sealing and dust proof :Dust collection box is available, it can reduce the dust

Description

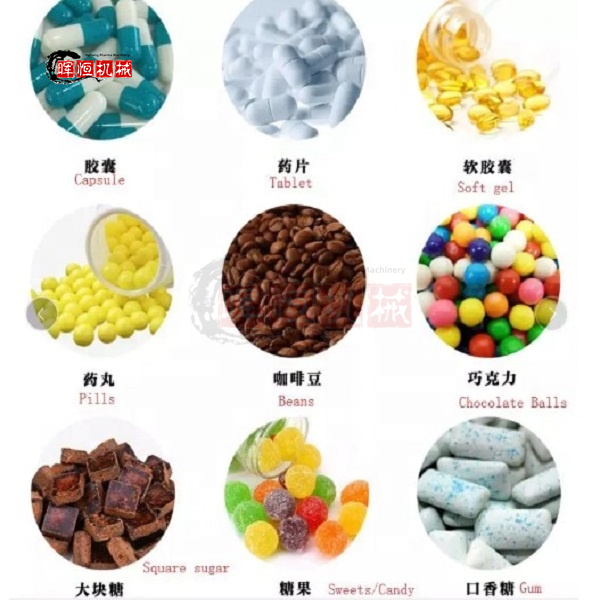

Application

Automatic Electronic counting machine is special for counting tablets, soft gelatin, hard capsule and chewing gums, etc. This machine adopts 8 sets imported counting sensor for counting with 8 Guiding Way and two head. The advantage of the machine is no need change mould when you change the counting object, only adjusting the counting table height by Easy Adjust wheel. The machine comes with Touch screen operation and PLC Control for convenient running.

The block bottle device on the passing bottle-track of the conveying bottle system make the bottles which came from the previous equipment stay in the bottling position,waiting to be filled in.The medicine goes into the medicine container in order by the vibration of the feeding corrugated plate.There’s a counting photo electronic sensor installed on the medicine container,after counting of the medicine in the medicine container by the counting photo electronic sensor, the medicine goes into the bottle in the bottling position.

Feature

- Strong compatibility,It can count and bottle various kind of solid preparation or solid granules for example, tablet (including heteromorphism tablet)、capsule、softcapsule( transparent and non-transparent)、pill etc.

- Vibration cutting: 16 channel vibration under homogeneous materials, unique patent agencies blanking, turning out material is steady, not damage

- Anti high dust :Adopting the anti high dust photo electronic sensing technology onlydeveloped by our company ,it also can work stably under the high dust circumstance.

- Correct counting :With automatic photo electronic sensor counting ,the error of bottling is less than nation standard.

- Special structure of the discharge spout, can prevent blocking drugs, small bottle can fast bottling (optional)

- High intelligence :It has various alarm and control functions like no bottle no count,check fault automatically and so on.

- Auxiliary function :Photoelectric sensor can check automatically if there’s no bottle and stops automatically.

- Easy operation :Adopting intellectualized design, all kinds of operation data can beset according to the requirement .It can store 10 groups of setting parameters for use.

- Convenient maintenance :After simple training, the worker can operate easily.It is easyto disassembly, clean and change the components without any tools.

- Sealing and dust proof :Dust collection box is available, it can reduce the dust (Optional)

Technical Parameters

| MODEL | SHH-SL8 | SHH-SL12 | SHH-SL16 | SHH-SL24 | SHH-SL32 | SHH-SL48 |

|

Applicable Bottle Type |

Bottle diameter 50mm, height 180mm or less | |||||

| Production Capacity(bottles/min) | 20-30 | 20-50 | 20-70 | 20-90 | 40-120 | 40-150 |

| Bottle Capacity Setting Range(pcs/bottle) | 1-9999 | |||||

| Power Supply And Power | 220V/50HZ 0.6KW | 220V/50HZ 0.75KW | 220V/50HZ 1.1KW | 220V/50HZ 1.2KW | 220V/50HZ 2.2KW | 220V/50HZ 2.5KW |

| Weight(kg) | 250 | 340 | 480 | 500 | 550 | 680 |

| Overall Size(mm) | 1400×1400×1560 | 1360×1530×1700 | 1560×1530×1700 | 1800×1400×1680 | 2200×1400×1680 | 2160×1650×1700 |

Tablet Example

Video

Related Products

Contact Us

Phone

008613166139318

kevinpharmachinery@gmail.com

kevin-pharmachinery

Get in Touch with Us

Contact Us

Our professional team will reply to you as soon as possible.

kevinpharmachinery@gmail.com

WhatsApp/Phone/Wechat

008613166139318

Company name

Shanghai Huiheng Pharmaceutical Machinery Co., Ltd.