Product

Injection Vial Bottle Washing Filling Stoppering Capping Machine

Details:

- Application range: glass vial, small round bottle, customized bottle.

2. Install with imported peristaltic pump, it has high filling accuracy. Suitable for many volume filling demands.

3. The conjunction between the tabletop and support column that above table was designed as chamfer type, tidy and beautiful, no blind corner of cleaning.

4. Possess function: rejecting away the fallen vial, no filling if lacks vial, no stoppering if lacks vial.

Description

Application

It is mainly used for filling and plugging of vial liquid and lyophilized products in pharmaceutical factories.

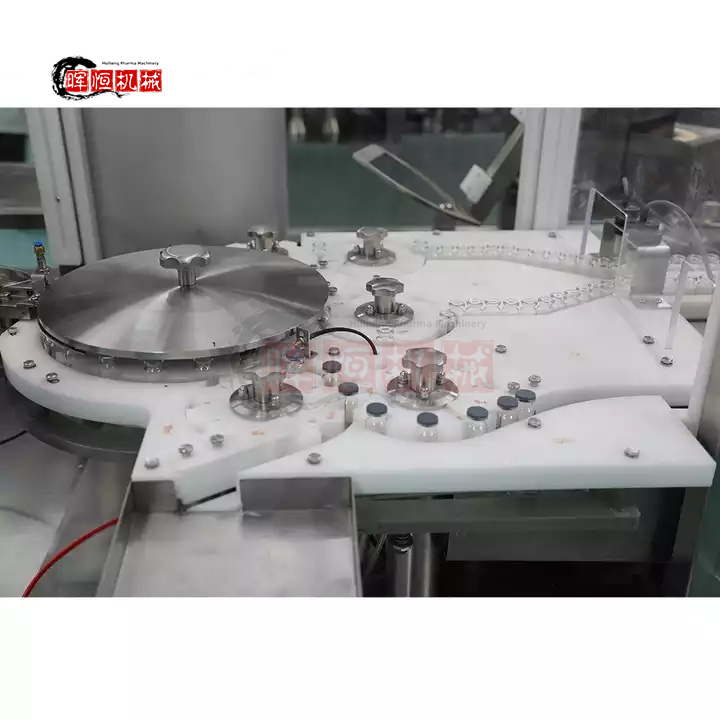

This machine adopts single row synchronous belt for conveying, and servo motor control for following movement: filling needle up and down & fro and back, integral type sucker plugging and outfeed. It can automatically finish procedures of vial orienting, conveying,(pre-nitrogen), filling, (post-nitrogen), stopper orientation, plugging etc. For the plugging, it can do full plugging and half plugging.

Based on all kinds of advanced technology in company, together with the filling principle, we designed and developed this kind of high speed sterile filling machine with all servo system. There are options for ORABS, IPC weighing system, CIP&SIP for filling system. The high configuration of this method can fully meet EU cGMP standard.

Feature

- Application range: glass vial, small round bottle, customized bottle.

2. Install with imported peristaltic pump, it has high filling accuracy. Suitable for many volume filling demands.

3. The conjunction between the tabletop and support column that above table was designed as chamfer type, tidy and beautiful, no blind corner of cleaning.

4. Possess function: rejecting away the fallen vial, no filling if lacks vial, no stoppering if lacks vial.

5. It has a one-key calibration function for filling volume, easy and visualized setting.

6. The stoppering stroke can be regulated, both full-stoppering and semi-stoperring products are suitable.

7. Can install with ORABS/CRABS grade purifying LAF protection hood to realize no interrupt production inside machine (Optional).

8. Can equip with online LAF monitor system, detection the air speed, dust particle and etc, to meet GMP manufacture requirements.(Optional).

9. Can custom design equipment according to user production requirement.

Technical Parameters

| Model | Suitable sizes | Capacity | Filling heads | Plugging heads | Power | Net weight | Overall dimensions |

| SHH-GZ12 | 2-30ml vial | 6000-24000pcs/h | 12 | 24 | 17kw | 2000kg | 4670*2150*1850mm |

| SHH-GZ12/10 | 6000-20000pcs/h | 10 | 16kw | ||||

| SHH-GZ12/8 | 6000-16000pcs/h | 8 | 15kw | ||||

| SHH-GZ12/6 | 2-100ml vial | 3000-12000pcs/h | 6 | 12/24 | 14kw | ||

| SHH-GZ6 | 2-30ml vial | 3000-12000pcs/h | 6 | 14kw | 1500kg | 3950*1950*1850mm | |

| SHH-GZ6/4 | 3000-7200pcs/h | 4 | 13kw | ||||

| SHH-GZ6/2 | 2-100ml vial | 1000-3600pcs/h | 2 | 12kw |

Tablet Example

Video

Related Products

Contact Us

Phone

008613166139318

kevinpharmachinery@gmail.com

kevin-pharmachinery

Get in Touch with Us

Contact Us

Our professional team will reply to you as soon as possible.

kevinpharmachinery@gmail.com

WhatsApp/Phone/Wechat

008613166139318

Company name

Shanghai Huiheng Pharmaceutical Machinery Co., Ltd.

压塞机-5.jpg)