Product

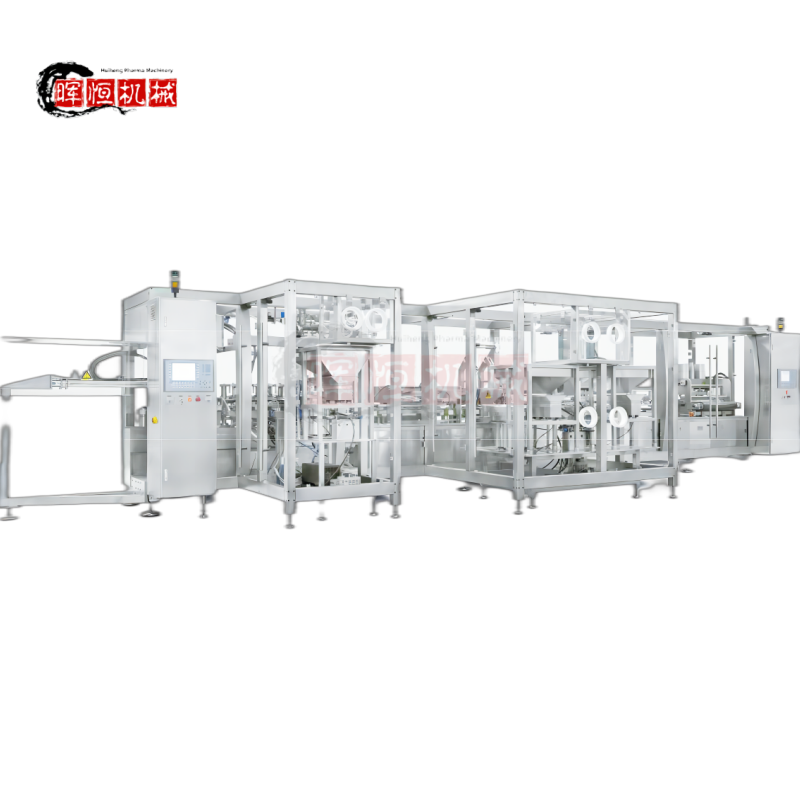

Non-PVC Soft Bag IV Solution Forming Filling Production Line

Details:

1. Compact integrated design of wash-fill-seal with smaller production area

2. Applicable to any round or flat IV solution bottles with different shapes

3. Voice alarm when fault, and machine halt

4. PLV control, all operation data can be set, changed and kept on file

5. CIP/SIP on line

Description

Application

HUIHENG PHARMA proudly presents its cutting-edge Non-PVC soft bag IV solution production line, incorporating the latest advancements in technology. This sophisticated system seamlessly executes film feeding, printing, bag manufacturing, filling, and sealing within a single, integrated machine.

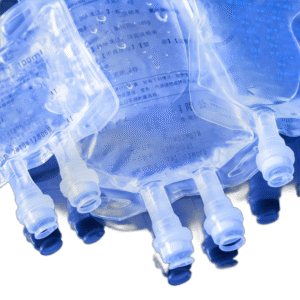

Engineered for adaptability, our production line accommodates 50-5000ml Non-PVC soft bags, catering to a diverse array of solutions, including general, special, dialysis, parenteral nutrition, antibiotics, irrigation, and disinfectant solutions. The machinery offers an extensive range of PP bag designs, featuring options such as single boat-type ports, single/double hard ports, double soft tube ports, and more.

Experience unparalleled precision and flexibility in IV solution manufacturing through HUIHENG PHARMA’s state-of-the-art production solutions.

This holistic approach to automation enhances productivity and minimizes the risk of human error, resulting in Non-PVC soft bags of the highest quality. The synchronized coordination of film feeding, printing, bag making, filling, and sealing exemplifies the cutting-edge capabilities of HUIHENG PHARMA’s production line, positioning it at the forefront of modern manufacturing in the healthcare industry.

Feature

- 100% film utilization: No waste edge between bags, reducing both material and energy consumption.

- Reliable heating and welding system: Leakage rate less than 0.03%.

- Quick changeover: 0.5-1 hour to switch from one size to another.

- Compact structure, reduce 1/3 length of the machine, save room space and running cost.

- Stable running and transmission system: only need 1 control system, 1 HMI and 1 operator.

- Safe filling nozzle: No solution overflows, no particles generation.

- Auto detection and faulty rejection system.

Technical Parameters

| Item | Main Content | ||||||||

| Model | SHH-SRD1A | SHH-SRD2A | SRS2A | SHH-SRD3A | SHH-SRD4A | SRS4A | SHH-SRD6A | ||

| Actual Production Capacity | 100ML | 1000 | 2200 | 2200 | 3200 | 4000 | 4000 | 5500 | |

| 250ML | 1000 | 2200 | 2200 | 3200 | 4000 | 4000 | 5500 | ||

| 500ML | 900 | 2000 | 2000 | 2800 | 3600 | 3600 | 5000 | ||

| 1000ML | 800 | 1600 | 1600 | 2200 | 3000 | 3000 | 4500 | ||

| Power Source | 3 Phase 380V 50Hz | ||||||||

| Power | 8KW | 22KW | 22KW | 26KW | 32KW | 28KW | 32KW | ||

| Compressed Air Pressure | Dry and oil-free compressed air, the cleaness is 5um,the pressure is over 0.6Mpa.The machine will automatically warn and stop when the pressure is too low | ||||||||

| Compressed Air Consumption | 1000L/mim | 2000L/mim | 2200L/mim | 2500L/mim | 3000L/mim | 3800L/mim | 4000L/mim | ||

| Clean Air Pressure | The pressure of clean compressed air is over 0.4Mpa, the cleaness is 0.22um | ||||||||

| Clean Air Consumption | 500L/min | 800L/min | 600L/min | 900L/min | 1000L/min | 1000L/min | 1200L/min | ||

| Clean Air Consumption | 500L/min | 800L/min | 600L/min | 900L/min | 1000L/min | 1000L/min | 1200L/min | 2000L/min |

| Cooling Water Pressure | >0.5kgf/cm2 (50kpa) | |||||||

| Cooling Water Consumption | 100L/H | 300L/H | 100L/H | 350L/H | 500L/H | 250L/H | 400L/H | 800L/H |

| Nitrogen Consumption | According to the customer’s special requirements, we can use the nitrogen to protect the machine, the pressure is 0.6Mpa. The consumption is less than 45L/min | |||||||

| Running Noise | <75dB | |||||||

| Room requirements | Temperature of the environment should ≤26℃, the humidity: 45%-65%, Max. humidity should less than 85% | |||||||

| Overall Size | 3.26×2.0×2.1m | 4.72×2.6×2.1m | 8×2.97×2.1m | 5.52×2.7×2.1m | 6.92×2.6×2.1m | 11.8×2.97×2.1m | 8.97×2.7×2.25m | 8.97×4.65×2.25m |

| Weight | 3T | 4T | 6T | 5T | 6T | 10T | 8T | 1 |

Tablet Example

Video

Related Products

Contact Us

Phone

008613166139318

kevinpharmachinery@gmail.com

kevin-pharmachinery

Get in Touch with Us

Contact Us

Our professional team will reply to you as soon as possible.

kevinpharmachinery@gmail.com

WhatsApp/Phone/Wechat

008613166139318

Company name

Shanghai Huiheng Pharmaceutical Machinery Co., Ltd.