Product

Normal Saline BFS Blowing Filling Sealing Machine

Details:

1. Extrude plastic particles into plastic perform at high temperature.

2. Then the preform is blown into a container by sterilized and filtered air.

3. Filling liquid that has been sterilized and filtered.

4. Tight sealing of containers after filling.

5. BFS machine is suitable for liquid filling in pharmaceutical, chemical, and food industries with aseptic or non-aseptic packaging in plastic containers.

Description

Application

Main Application

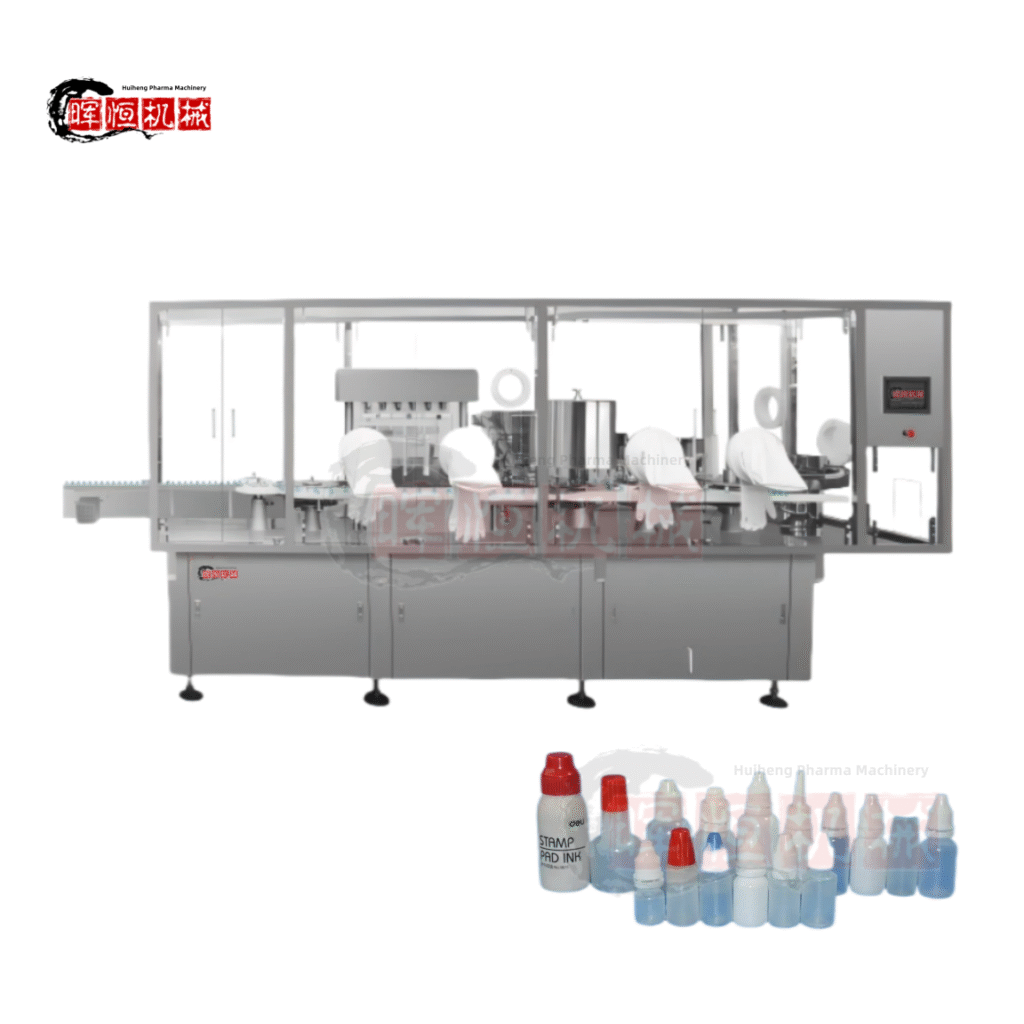

Shanghai Huiheng Pharmaceutical Aseptic BFS Filling Machine for plastic ampoule (BFS machine) is an advanced technology that integrates molding, filling, and sealing under complete control, which enables liquid to be packaged in polypropylene/high-density & low-density polyethylene plastic bottle, and the whole production process automatically completes the followings in a controlled environment (aseptic environment):

1. Extrude plastic particles into plastic perform at high temperature.

2. Then the preform is blown into a container by sterilized and filtered air.

3. Filling liquid that has been sterilized and filtered.

4. Tight sealing of containers after filling.

5. BFS machine is suitable for liquid filling in pharmaceutical, chemical, and food industries with aseptic or non-aseptic packaging in plastic containers.

Feature

Characteristics

1.The design, MOC, manufacturing, assembly, and debugging of the Pharmaceutical Aseptic Blow Fill Seal BFS system meet the requirements of the new GMP standards for drug production.

2.Advanced equipment, unique and reasonable structure, stable and reliable performance.

3.Applicable Specification: 0.2ml-1000ml plastic bottle (as per user’s requirements).

4.Production Capacity: 1000-18000BPH for Pharmaceutical Aseptic Blow Fill Seal BFS system

5.The number of bottles made each time: 1-30 bottles/mold, can be selected based on production capacity.

6.Filling Accuracy: ≤ ±1% (according to drug characteristics)

7.The BFS machine is integrated with bottle-making, filling, and sealing, with compact structure and occupies a small area, which reduces clean workshop area and saves energy consumption of air conditioning unit, as well as investment and use cost.

8.The plastic particles are plasticized by a low-speed long screw extruder driven by a specially designed servo motor, which can effectively reduce thermal stress of the material and accurately control the size of bottle preforms.

9.Each working cycle of the equipment can be compared and controlled automatically, with real-time feedback.

Technical Parameters

| 1

|

Each cavity output capacity Recommend bottle type |

0.4~1ml | 2500±10% pcs/h | Eye drops 10 pcs/cavity, bottle width 11.5 mm |

| 0.4~1ml | 2060±10% pcs/h | Eye drops 8 pcs/cavity, bottle width 11.7 mm | ||

| 2ml | 2060±10% pcs/h | Ampoule 8 pcs/cavity, bottle width 11.7 mm | ||

| 2ml | 1520±10% pcs/h | Ampoule 6 pcs/cavity, bottle width 12.5 mm | ||

| 5~20ml | 1250±10% pcs/h | Ampoule 5 pcs/cavity, bottle width 18.3 mm | ||

| 2

|

Production capability Recommend bottle type |

Each cavity output capacity ×Mold chamber quantity |

Actual output capacity depends on the dimension of product and plastic particles | |

| 0.4~1ml | 2600±10% pcs/h | Eye drops 10 pcs/cavity, bottle width 11.5 mm | ||

| 0.4~1ml | 2060±10% pcs/h | Eye drops 8 pcs/cavity, bottle width 11.7 mm | ||

| 2ml | 2060±10% pcs/h | Ampoule 8 pcs/ pcs/cavity, bottle width 11.7 mm | ||

| 2ml | 1520±10% pcs/h | Ampoule 6 pcs/ pcs/cavity, bottle width 12.5 mm | ||

| 5~20ml | 1250±10% pcs/h | Ampoule 5 pcs/ pcs/cavity, bottle width 18.3 mm | ||

| 3 | Filling error range | Compliant with pharmacopoeia | ||

| 4 | Weight error range | ±0.3g | Raw material of same batch | |

| 5 | Container thickness error | ±0.1mm | ||

| 6 | Product qualification rate | ≧98% | ||

| 7 | Product quality | Compliant with relevant quality standard | Transparency, sealing, strength, appearance | |

Tablet Example

Video

Related Products

Contact Us

Phone

008613166139318

kevinpharmachinery@gmail.com

kevin-pharmachinery

Get in Touch with Us

Contact Us

Our professional team will reply to you as soon as possible.

kevinpharmachinery@gmail.com

WhatsApp/Phone/Wechat

008613166139318

Company name

Shanghai Huiheng Pharmaceutical Machinery Co., Ltd.