Product

PP Bottle LVP I.V. Solution Washing Filling Sealing Labeling Machine

Details:

1.Servo drive and stable during high-speed movement, the positioning is accurate, durable, and the maintenance cost is low.

2.The cam clamping fingers without plastic scrap and powder to ensure product quality.

3.High production capacity: range from 4000-15000bottles per hour.

4.Closed integral chain structure, precise center distance, rings and other foreign objects cannot enter the chain, easy maintenance.

5.The sealing does not air leak, improve the blowing efficiency, shorten the bottle forming time.

Description

Application

Descriptions:

SHH-XGF PP Bottle LVP Wash-Fill-Seal Machine has three sections, ionic air washing or ionic air plus water washing, constant pressure filling, and hot melting sealing.

It can automatically finish the processes of bottle feeding, bottle entering, bottle reversing by manipulator, ionic air reversely blowing and washing, bottle conveying, fixed volume filling, cap sorting, cap feeding, simultaneously heating cap and bottleneck, air eliminating, hot melting sealing, bottle conveying out etc.

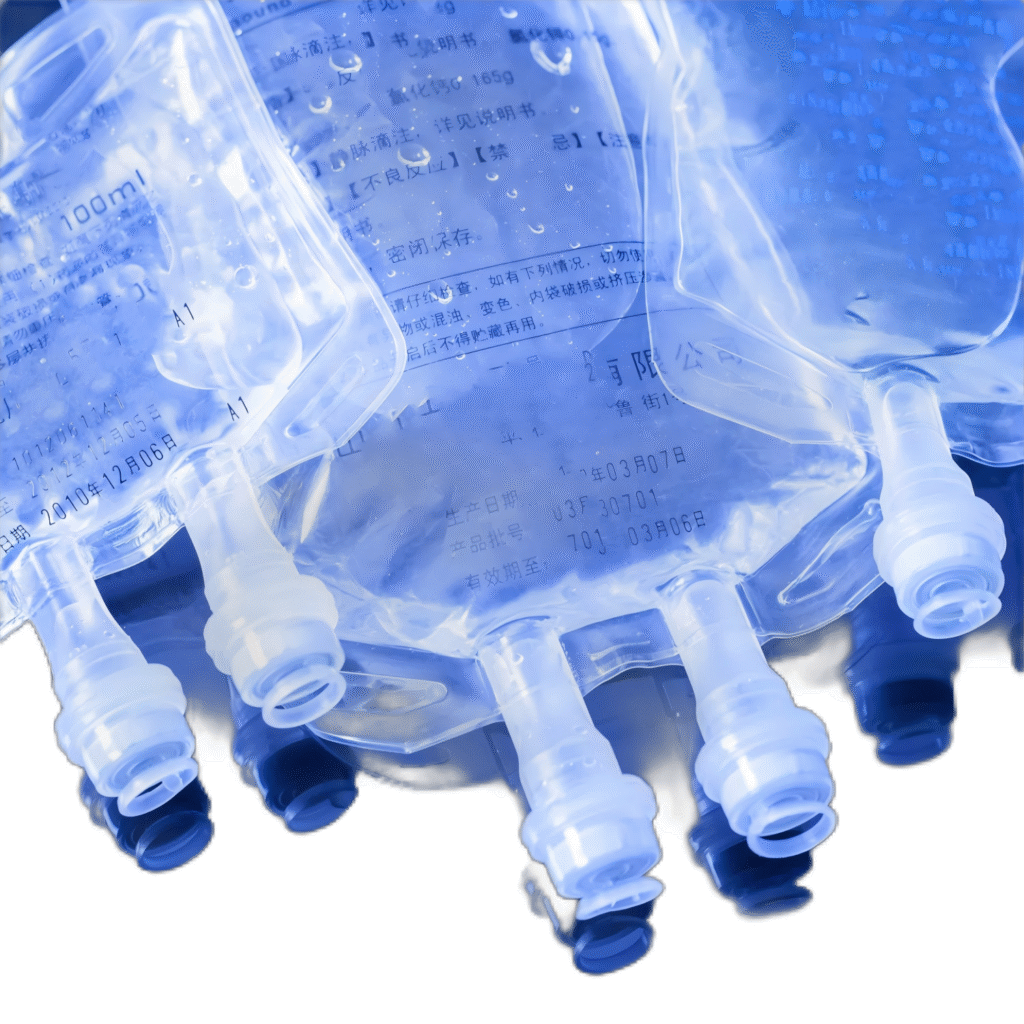

It is mainly applied to the washing, filling and sealing production for PP plastic soft and hard bottle large volume parenteral, like glucose infusion, sodium chloride infusion, sodium chloride and dextrose injection, metronidazole injection etc.

Feature

1. Compact integrated design of wash-fill-seal with smaller production area

2. Applicable to any round or flat IV solution bottles with different shapes

3. Voice alarm when fault, and machine halt

4. PLV control, all operation data can be set, changed and kept on file

5. CIP/SIP on line

Technical Parameters

| Item | Data |

| Production capacity | 2000~20000 bottles/hour |

| Specification | 50~1000ml round or other shape PP bottle |

| Bottle washing | ionic air washing, or ionic air and water washing |

| Main filling medium | Liquid such as large volume infusion |

| Filling error | ±1% |

| Liquid filling temperature and pressure | 40~55℃ 0.6~2kg/cm² |

| CIP/ SIP | 125 ℃–30 min |

| Air consumption (clean air) | Pressure: 0.6~0.8Mpa 180(120)m³/h |

| Cooling water | 250L/h, 15~20℃ |

| Noise | max.75dB |

| Electric capacity | 18~35KW |

Tablet Example

Video

Related Products

Contact Us

Phone

008613166139318

kevinpharmachinery@gmail.com

kevin-pharmachinery

Get in Touch with Us

Contact Us

Our professional team will reply to you as soon as possible.

kevinpharmachinery@gmail.com

WhatsApp/Phone/Wechat

008613166139318

Company name

Shanghai Huiheng Pharmaceutical Machinery Co., Ltd.