Product

SHH-FL Series Fluid Bed Dryer Granulator

Details:

1.Because of powder Granulation, the fluidity is improved and the dust is reduced;

2.Because of powder Granulation , its solving property is improved ;

3.The operation of equipment is safe because the anti static filtering cloth is adapted;

4.The equipment has no dead corner. Therefore the loading and unloading are quick and light and clean. It can meet the requirements of GMP

Description

Application

The powder grannle in the container (fluidization)appear in the state of fluidization. It is preheated and mixed with chen and heated air. At the same time the solution of adhesive solvent is fogged and sprayed into the container. It makes the some particles become granulating that contains adhesive. Being of unceasing dry through hot air, the moisture in the granulation is evaporated and the adhesive is solidification. The process is carried out continuously. Finally it forms ideal, uniform and Porous granules

1.Pharmaceutical industry: tablet, capsule, low sugar or no sugar granule of chinese medicine

2.Foodstuff: cocoa, coffee, milk powder, juice of granulate, flavoring and so on

3.Other industries: pesticide, feed chemical fertilizer, pigment, dyestuff and so on

4.powder or granular drying of the wet material.

5.Coating: granule, pill protection layer, prepare color, slow-release, the film, enteric coated

Feature

1.Because of powder Granulation, the fluidity is improved and the dust is reduced;

2.Because of powder Granulation , its solving property is improved ;

3.The mixing, Granulation and drying can be completed in one step inside the machine;

4.The operation of equipment is safe because the anti static filtering cloth is adapted;

5.The operating personnel can not be damaged if explosion take place because there is releasing hole;

6.The equipment has no dead corner. Therefore the loading and unloading are quick and light and clean. It can meet the requirements of GMP

Technical Parameters

| Item | Unit | Type | ||||||||||

| 3 | 5 | 15 | 30 | 60 | 120 | 200 | 300 | 500 | 800-1000

Design according to user requirements |

|||

| Container | Volume | L | 12 | 22 | 45 | 100 | 220 | 420 | 670 | 1000 | 1500 | |

| Capacity | Min Dia | mm | 300 | 400 | 550 | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | |

| Kg | 1.5 | 4 | 10 | 15 | 30 | 80 | 100 | 150 | 250 | |||

| Fan | Max.

Blast Capacity |

Kg m/h | 4.5 1000 | 6

1200 |

20

1400 |

45

1800 |

90

3000 |

160

4500 |

300

6000 |

450

7000 |

750

8000 |

|

| Air Pressure | H₂O

mm |

375 | 375 | 480 | 480 | 950 | 950 | 950 | 950 | 950 | ||

| Power | kw | 3 | 4 | 5.5 | 7.5 | 11 | 18.5 | 22 | 30 | 45 | ||

| Steam expenditure | Kg/h | 15 | 23 | 42 | 70 | 141 | 211 | 282 | 366 | 451 | ||

| Compressed air expenditure | m³/min | 0.9 | 0.9 | 0.9 | 0.9 | 1.0 | 1.0 | 1.1 | 1.5 | 1.5 | ||

| Weight of the main body | Kg | 500 | 700 | 900 | 1000 | 1100 | 1300 | 1500 | 1800 | 2000 | ||

| Steam pressure | Mpa | 0.3-0.6 | ||||||||||

| Temperature | ℃ | -120℃

(Room temperature can be adjusted in the range) |

||||||||||

| Working time | Min | 45~90 (Depends on the characteristics of the material) | ||||||||||

| Material Yield | % | ≥99 | ||||||||||

| Noise | dB(A) | The fan is isolated from the host, ≤75dB(A) | ||||||||||

| Size(L×WxH) | M | 1.0*0.6*2.1 | 1.2*0.7*2.1 | 1.25*0.9*2.5 | 1.6*1.1*2.5 | 1.85*1.4*3 | 2.2*1.65*3.3 | 2.34*1.7*3.8 | 2.8*2.0*4.0 | / | ||

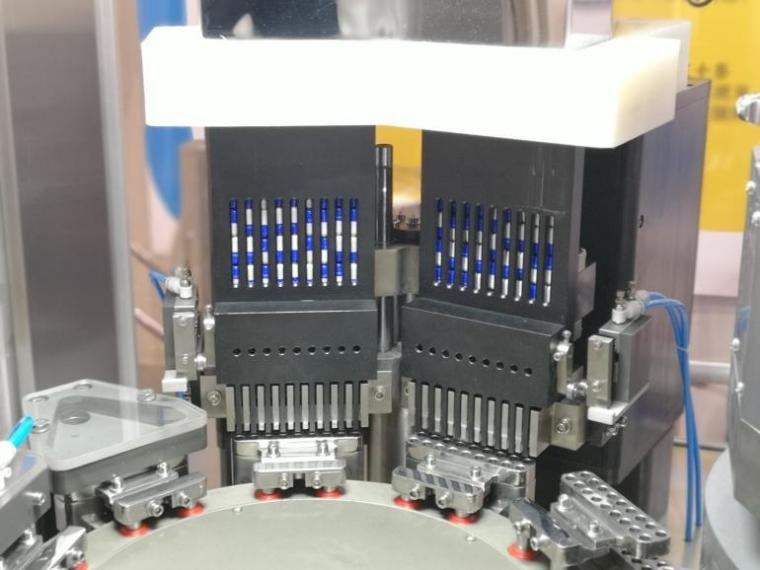

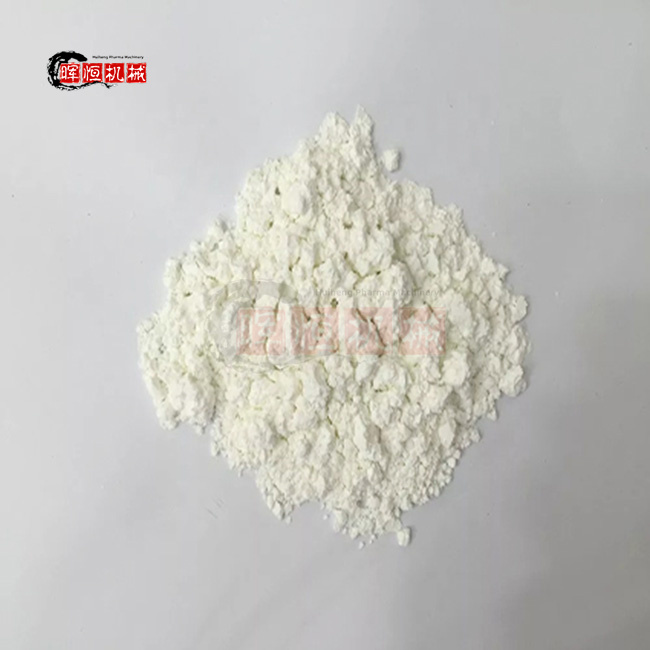

Tablet Example

Video

Related Products

Contact Us

Phone

008613166139318

kevinpharmachinery@gmail.com

kevin-pharmachinery

Get in Touch with Us

Contact Us

Our professional team will reply to you as soon as possible.

kevinpharmachinery@gmail.com

WhatsApp/Phone/Wechat

008613166139318

Company name

Shanghai Huiheng Pharmaceutical Machinery Co., Ltd.